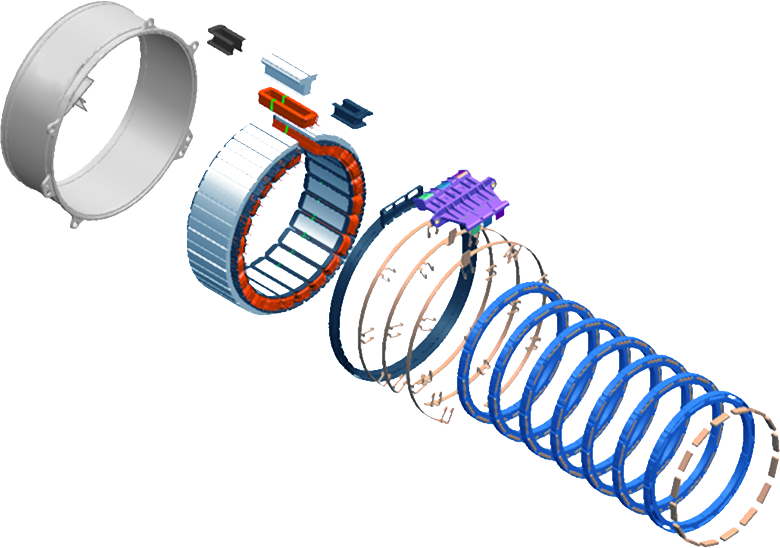

High efficiency / Low losses

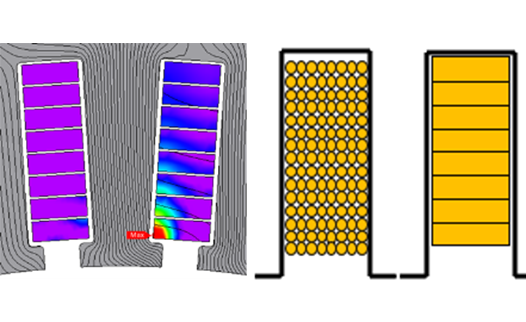

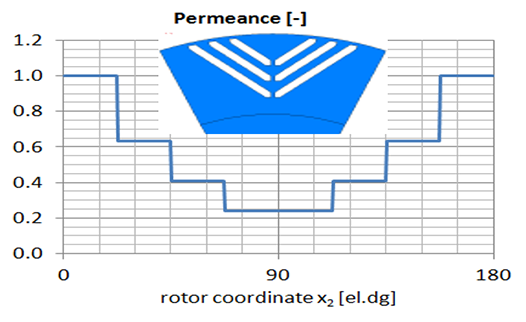

Double/Multi-magnet layout has advantage to decrease the harmonic core losses

PIN flat wire can increase remarkably the slot factor

Multi-PIN design(6-8PIN)depress the skin and proximity effect

High flat ratio design for high efficiency at speed area

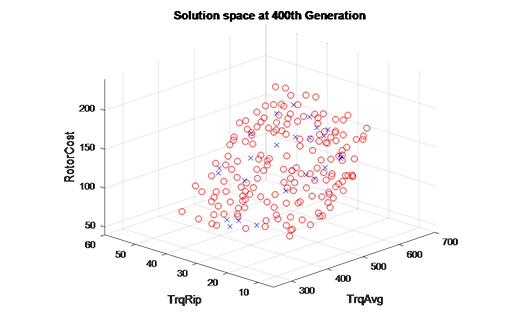

Characteristic

Characteristic Customer revenue

Customer revenue Manufacturing

Manufacturing