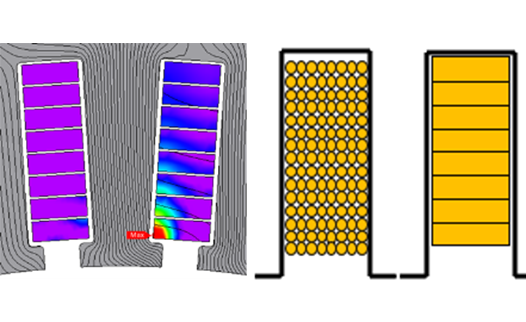

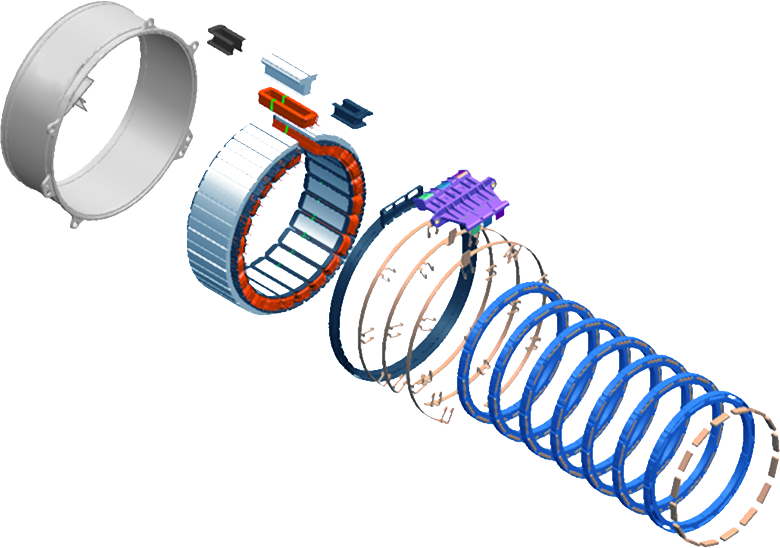

The stator adopts a split core structure with high slot full rate and high efficiency, which is convenient for mass production

The production line occupies a small area, the cost of raw materials is low, and the supplier system is mature

The mechanical design is compact. The product deforms easily. The production can be expanded.

The stator adopts a concentrated winding structure with short winding ends

The stator end windings potting, good heat dissipation, higher continuous power and torque output

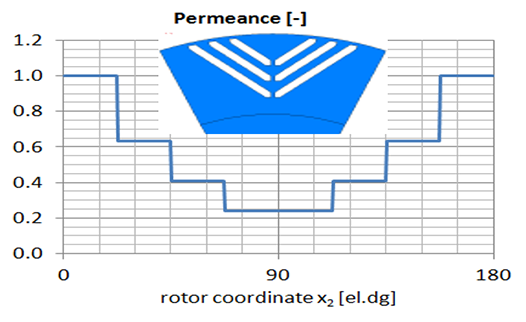

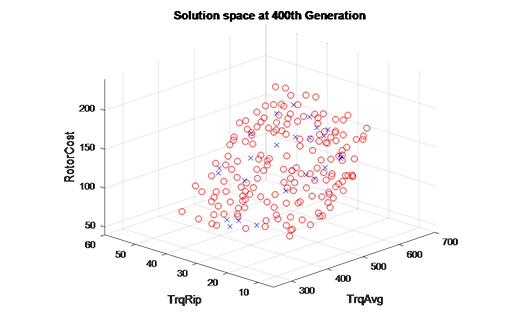

Rotor anti-demagnetization permanent magnet steel design, safe and reliable

Water-cooled chassis, high power torque density

Characteristic

Characteristic Customer revenue

Customer revenue Manufacturing

Manufacturing